How Greenprint Agave Straws and Products Are Made

Background

Our mission at Greenprint is to fundamentally combat the global plastic crisis by providing viable and realistic single-use disposable product solutions. Easier said than done! Given changing regulations, the lack of consumer awareness, and the mediocre infrastructure required to handle waste, it has become increasingly complex to offer sustainable packaging solutions properly.

Of the 380 million metric tons of plastic produced annually, most end up in landfills or the environment. Around 10% is incinerated, and it is estimated that 6-9% is recycled. We’ve designed our products to degrade where the probability of them ending up is the highest. Our biobased products are designed to degrade in a landfill optimally, and our compostable products are designed to compost in industrial composting facilities.

Agro-industrial Waste Collection

Nutrient and mineral-rich fibers are used across various industries – prevalent in our food supply chains, pet food, cattle feed, and many other applications where it profoundly impacts sustainability. Focusing on regionally abundant plant waste, we’ve found agave fibers, sugar cane, cassava, and wood fibers work best with our processes.

We’ve primarily focused on sourcing FSC-certified waste fibers with partial to no nutrient or mineral remains, which are entirely purposeless in any other sector. So here’s where our products are born. We’re upcycling plant waste and giving it another purpose.

Scattered over a variety of suppliers across the Americas, we’ve managed to put together a fiber recollection system, successfully homologating quality and control, assuring very low product variation with a raw material that’s constantly changing.

Material Compounding

Agave has a wide variety of species; it’s the mother plant for well-known liquors such as tequila and mezcal – our primary source of fiber. It is vastly grown across various regions of Mexico, where it’s treated and drained by the liquor industry, left with difficult-to-treat sugars incompatible with traditional polymers.

There is a proprietary process in making the fiber compatible with any polymer, ranging from standard PP/PE/PS plastics to PLA/PHA’s and other plant-driven polymer extracts.

This is what sets us apart, offering solutions across the entire spectrum of sustainability. We develop materials to meet criteria and legislation.

- Our greenprint industrial compostable product line is certified by BPI and TUV Austria.

- Our greenprint biobased product line is certified to biodegrade over 95% in the first 180 days*1, third-party tested according to ASTM D6400 and D5511 regimens, guaranteeing the determination of the biodegradability of the products.

*1 having reached an active landfill, 1-5 years otherwise

Final Product Transformation

- Extrusion (Straws and Stirrers)

- Injection (Cutlery, bottle caps, accessories)

- Thermoforming (Plates, containers, lids)

- Paper Transformation (Paper Cups)

Our manufacturing capabilities go way beyond straws – our state-of-the-art polymer compounding has allowed us to formulate a raw material compatible with traditional manufacturing processes – with slight modifications.

Coupling the right material with the indicated process and parameters is critical to obtaining a functional, sustainable product.

Which product is for you?

Compostable vs. Biobased

It’s important to know if your community has a composting program and double check the compost center near you accepts biosolids (bioplastics). If so, this is the right product for you.

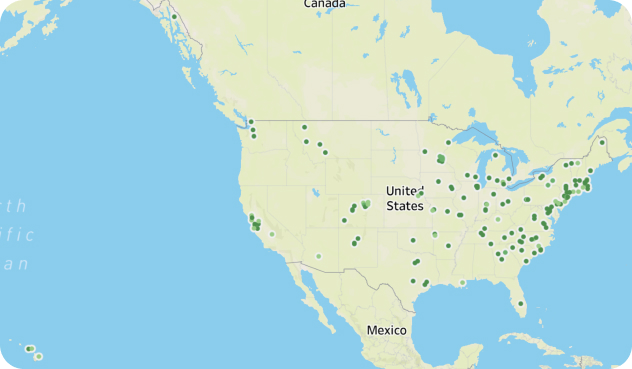

There are many communities where a composting program is not offered due to a lack of a proper waste collection and separation system and/or a composting facility in proximity. This map can help you locate a facility and check if your community offers the proper waste collection service.

If a compostable product is thrown away with regular trash, it will not decompose and make other plastic products impossible to recycle. So if you are not actively and consciously composting, the compostable product line is not for you, regardless of what legislation might say.

If that’s the case, our biobased product line is right for you. Designed to degrade over 95% in the first 180 days in a biologically active landfill, you can dispose of these products with your regular trash without infecting the waste stream. These will decompose over a period of time or enter another life cycle with recycled plastics.

End Notes

We must understand the products we’re consuming and know that every small action we take will make a difference. The proper disposal of our single-use consumables is today the defining factor in combating our global plastic waste epidemic. Coupled with genuinely sustainable product solutions, ones that abide to waste management limitations, we’ll be able to decrease the plastic and waste that ends up on our streets, in our waterways, and in our food. It’ll undoubtedly require a team effort, plenty of awareness, and accurate information to begin to tackle this problem. Still, we’re convinced that it’s not only possible but also necessary.

References

- https://www.plasticsoupfoundation.org/en/plastic-problem/plastic-environment/plastic-production-decomposition/

- https://us.fsc.org/en-us/certification

- https://brightly.eco/blog/upcycling-meaning

- https://public.tableau.com/app/profile/olga2630/viz/CompostingFacilitiesintheUnitedStates/CompostingFacilitiesStory

- https://www.google.com/search?q=interstellas+final+docking+scence&rlz=1C5CHFA_enMX981MX981&oq=interstellas+final+docking+scence&aqs=chrome..69i57j33i10i160j33i22i29i30i625l2j33i22i29i30j33i22i29i30i625l5.11338j0j7&sourceid=chrome&ie=UTF-8#fpstate=ive&vld=cid:4ef313b3