Alternatives to Polystyrene

Polystyrene is a type of plastic made by polymerizing styrene. This process forms a base product for making appliances, toys, auto parts, electronics, plant pots, and more.

Reduce your carbon footprint and tread lighter on this beautiful planet by switching from single-use polystyrene items to a more eco-friendly alternative. Many polystyrene alternatives are environmentally friendly and functional. By knowing what alternative options are available, you can make the best choice for your business.

What Is Polystyrene?

Polystyrene (PS) is a versatile type of plastic used to produce many consumer goods. Manufacturers make polystyrene from polymerizing styrene, a fundamental chemical commonly found in the manufacturing of various items.

Polystyrene packaging comes in two forms: solid or foam (expanded). Manufacturers combine solid polystyrene with additives, other plastics, and colorants to make toys, electronics, and even plastic automobile parts and cup lids—this material is everywhere.

You can also encounter expanded polystyrene (EPS) daily. Polystyrene packaging peanuts safeguard fragile items during transport, and you might find EPS foam boards tucked away inside your walls, roof, and floors to provide basic thermal insulation. The food industry uses EPS for fast-food packaging with polystyrene cups and takeout containers.

EPS reigns in the realm of single-use plastics. We can attribute its widespread use to its remarkably lightweight and water-resistant qualities and low manufacturing costs. People sometimes refer to EPS in the food industry as “Styrofoam,” but this term is a Dow Chemical Company registered trademark that refers to the company’s branded building material products.

Polystyrene and Food Packaging

You’ll find polystyrene everywhere, from yogurt containers and coffee cups to packaging for meat, eggs, and fish. Solid and foam polystyrene food packaging products are common in the food industry. Solid polystyrene is used for:

- Straws

- Utensils

- Bowls

- Plates

- Beverage cups and lids

- Clear food containers

EPS is used for:

- Clamshell food containers

- Bowls

- Insulated beverage cups

- Trays

You can utilize the ASTM International Resin Identification Coding System (RIC) to identify polystyrene — if the number six appears on your packaging products, they are made from polystyrene. RIC utilizes a symbol similar to the recycling symbol, but when you see the arrows forming a triangle with the number six in the middle, don’t be fooled — polystyrene is not commonly recycled. ASTM International has revised its RIC symbol — it now uses a solid triangle, but the old symbols are still in use.

The Impact of Polystyrene

The manufacturing process of polystyrene releases 50 chemical byproducts, which can contaminate the surrounding air and water. Additionally, once it’s manufactured, polystyrene doesn’t go away. Polystyrene foam is not biodegradable. Research suggests that plastic foam remains in our environment for thousands of years. Over time, plastic foam breaks down into tiny pieces, and animals, like seabirds, mistake it for food with detrimental consequences—they can starve to death as the plastic in their bellies causes a feeling of satiety.

To rid the environment of polystyrene, people can incinerate polystyrene products, but burning polystyrene also releases styrene gas and other toxins into the atmosphere.

Is Polystyrene Toxic?

Research has quieted debates about whether polystyrene is toxic to humans. The International Agency for Research and Cancer and the Department of Health and Human Services have confirmed that the styrene units in polystyrene are potential carcinogens.

Styrofoam poisoning is a real threat. If you store food and drinks in polystyrene containers, the styrene units can leach into food and beverages, endangering human health. Exposure to styrene can irritate the upper respiratory tract and gastrointestinal tract and can also irritate the eyes and skin. Prolonged exposure truly proves that this material is poisonous. It can lead to more severe symptoms like hearing loss, fatigue, depression, headaches, and impaired kidney function.

Alternative Packaging Solutions

You’ll easily find a better solution for your packaging needs as greener options are available in various materials—from bamboo to cornstarch. Here are four green options to choose from.

1. Mineral-Filled Polypropylene Containers

Incorporating minerals like calcium carbonate, glass fibers, mica, and talc into polypropylene containers strengthens the packaging and reduces manufacturing costs. The added minerals allow these containers to be more heat-resistant as they don’t lose their form when they’re filled with hot foods. These containers are also ideal for saucy foods as they are leak-resistant and non-absorbent.

Mineral-filled polypropylene containers are one of the most cost-effective polystyrene alternatives, but they’re still mostly made of plastic and are normally not accepted by recycling centers. Unfortunately, lots of these packaging solutions end up in landfills.

2. Bamboo Packaging

Bamboo is a type of grass, and it is one of the fastest-growing plants in the world. This abundant resource is an excellent polystyrene alternative as it is compostable and biodegradable. Bamboo is also exceptionally strong, and eco-friendly manufacturers use bamboo to make:

- Cups

- Plates

- Utensils

- Bowls

- Cones

- Bamboo catering supplies

3. Sugarcane Fiber Packaging

Sugarcane fiber, also known as bagasse, is the fibrous portion of a sugar cane stalk that remains after juice extraction. Usually, bagasse is discarded, burned, or used as fuel in sugar mills. However, sugarcane fiber is a highly renewable resource since green manufacturers utilize a byproduct from sugar production to make a brand-new item. This fiber biodegrades quickly, is easily recyclable, and composts at a composting facility without hassle.

This fiber can be used to produce trays, take-out containers, bowls, and plates that can withstand high temperatures and are soak-proof—making bagasse one of the best eco-friendly Styrofoam alternatives.

Greenprint proudly manufactures and retails sugarcane clamshells in an array of sizes and also sells bagasse plates.

4. Cornstarch Packaging

Cornstarch packaging, made from polylactic acid (PLA), is a much better alternative to polystyrene, and manufacturers offer many different cornstarch packaging solutions. Some of these solutions include:

- Meat trays

- Lids

- Plates

- Fast-food containers

- Cups

When properly disposed of, PLA products can serve as a fertilizer. Unfortunately, you need to dispose of PLA products at a composting facility — they will not decompose in your garden. If your area does not have a composting facility, you might want to opt for a different packaging solution.

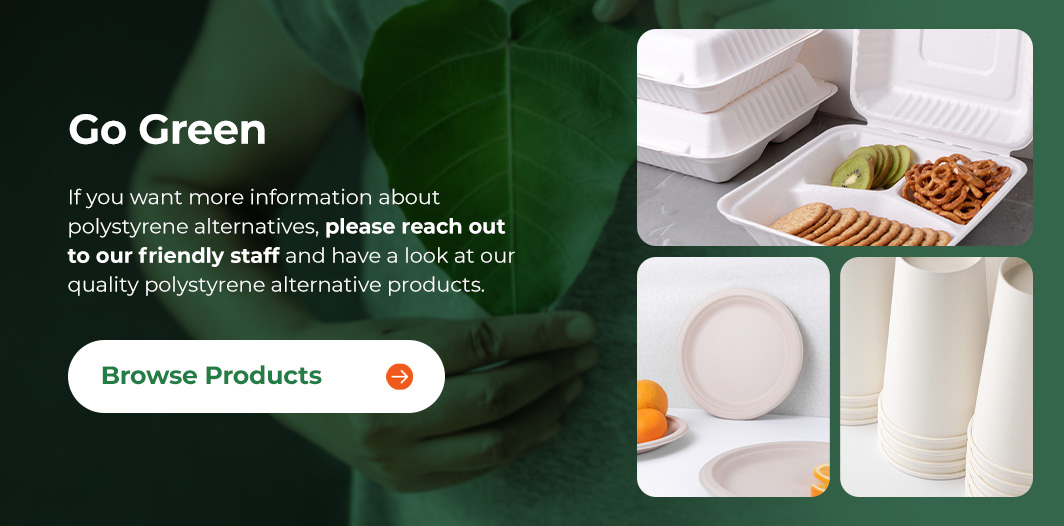

Go Green

Switching polystyrene packaging for greener alternatives safeguards you, your business, and your clients from the negative impact of polystyrene, and, of course, nature will thank you. If you want more information about polystyrene alternatives, please reach out to our friendly staff and have a look at our quality polystyrene alternative products.

References

- https://www3.epa.gov/ttnchie1/old/ap42/ch06/s063/final/c06s063_1995.pdf

- https://www.nationalgeographic.com/animals/article/whales-eating-plastic-pollution

- https://ntp.niehs.nih.gov/sites/default/files/ntp/roc/content/profiles/styrene.pdf

- https://www.osha.gov/styrene/hazards#:~:text=Health%20effects%20of%20styrene%20include,also%20result%20in%20gastrointestinal%20effects.